|

The source identification code - SID Code for CD and high density formt optical discs

The SID Code has become the industry standard for indicating the source of optical disc mastering or replication.

The SID Code represents quality and care and has now been adopted in over 80% of the world’s CD plants.

SID Code can be applied equally to CD and DVD, including all recordable forms of CD and DVD.

SID Code is compulsory under the SACD format specification.

Leading replicators are now using SID Code as a central part of their marketing strategy and quality control.

The leading replication industry trade body, IRMA requires use of source identifiers under the IRMA Anti-Piracy Compliance Program.

More and More content owners now stipulate that their products can only be produced in plants that have adopted and fully implemented the SID Code.

In an increasing number of countries there are now laws making the use of SID Codes mandatory.

SID Code is administered free of charge for the benefit of the replication industry and right owners by Philips and IFPI.

Background:

The Source Identification Code (SID Code) provides an optical disc production facility with the means to identify:

- all discs mastered and/or replicated in its plant, and

- the individual LBR/signal processor or mould that produced a particular stamper or disc.

Each production facility that wishes to implement the use of the SID Code is issued with its own unique code(s). The SID Code was developed for use with the CD format, but is now being used for both CD and High Density disc formats, including DVD and Super Audio CD.

The SID Code was developed jointly by copyright owners and the optical disc industry, primarily as an anti-piracy tool. However, since its introduction in 1994, the SID Code has proved a major benefit to optical disc producers. Its use both as a quality control tool and as a marketing tool has ensured that the SID Code, which was introduced on a purely voluntary basis, has now been implemented in over 80% of the world’s CD plants, representing over 90% of worldwide optical disc manufacturing capacity.

Why has the SID Code proved so popular with optical disc plants? The CEO of a leading independent optical disc producer says: “In an increasingly competitive, low-margin business, plants must do everything they can to attract high volume, high quality customers. The SID Code has been essential for this. My company takes pride in offering our customers complete security for their products. By ensuring that the SID programme has been meticulously implemented in all our plants worldwide we are able to show our customers that we take care of their intellectual property rights. The SID Code has been a vital ingredient in our growth strategy as more and more customers insist on having their discs produced exclusively in SID compliant plants.

The SID Code also fulfils a useful quality control function by allowing us to immediately identify the mould or Laser Beam Recorder that produced a particular disc.”

The adoption of the SID Code is direct result of proliferating optical disc piracy. This is an international problem. An organisation based in one country may place orders for the replication of pirate discs in a second country and distribute them in several others. International organised crime and even terrorist groups have been shown to be involved in optical disc piracy.

Optical discs are now used by the book publishing, computer software, film and record industries for distribution of their products. Many companies from each of these industries now require the use of the SID Code on all of their products, as an important tool in the fight against optical disc piracy.

In response to requests from replication and mastering facilities, the International Recording Media Association (IRMA) has created the Anti-Piracy Compliance Program. In order to be certified as compliant under the Program, a plant must incorporate a source identification code in the production of all masters stampers and optical discs.

The Recommendation:

It is recommended that all mastering and/or replicating facilities employ the code in their plants as the SID Code identification programme enhances the security of optical disc manufacturing at both the mastering and the replication stages.

Since not all plants have both mastering and replication facilities, there are two codes: a Laser Beam Recorder (LBR) Code, that identifies the plant that manufactured the master; and a Mould Code that identifies the plant where the disc was replicated.

When SID Codes are employed, every disc produced in a given plant carries the distinct code identifying that plant. Philips Electronics, as a licensor of CD and certain DVD technologies, allocates LBR and Mould SID Codes and any plant wanting to adopt the SID Code plan can obtain a code allocation(s) upon application to Philips.

It is important to note that a single SID Code allocation can be used for both CD format and high-density format (DVD or SACD) discs.

SID Codes are applied to all recordable and re-writeable formats of CD and DVD too.

The SID Code has achieved international recognition as the identification standard for all formats of optical discs, with over 80% of the world’s optical disc plants adopting the system. Whilst the SID Code programme is voluntary in most parts of the world it is now mandatory that all CDs (and other optical discs) replicated in Bulgaria, China, Hong Kong, Macau, Malaysia, Taiwan and the Ukraine carry SID Codes. Mandatory use of SID Code(s) is in prospect in several other countries, which are presently considering the introduction of regulations governing the optical disc manufacturing industry.

Who should implement the programme

- Those responsible for Optical Disc custom pressing purchases

- Those responsible for Optical Disc mastering and/or manufacturing

How to implement the programme

Obtaining and implementing the SID Code is simple and quick:

- Apply to Philips for your unique SID Codes. An application form can be obtained here or from Philips Intellectual Property & Standards, Business Support, Fax: +31 4027 32113

Or downloaded from http://www.licensing.philips.com/information/sid/

Philips has committed to promptly provide all bona fide applicants for SID Codes with the appropriate codes free of any administration or other charge.

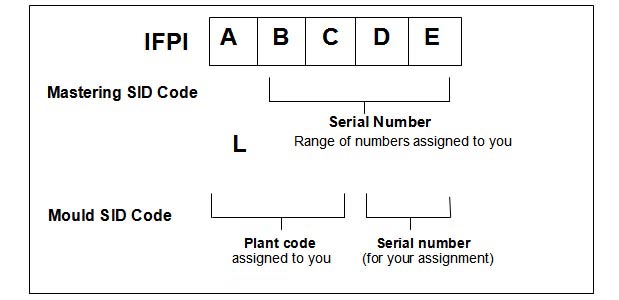

- Philips will issue the appropriate codes for your operation. Mastering Codes will be issued in a block of codes sufficient to meet the requirements of your operation. Mould Codes will consist of the letters IFPI followed by a four or five digit code The last two digits of this code are allocated by you to give each mould on the site, including spare moulds, a unique code. The first two digits (in the case of a four digit SID Code) or the first three digits (in the case of a five digit SID Code) are assigned to the operator of the manufacturing or mastering plant by Philips Intellectual Property & Standards.

Example: A Mould SID Code of IFPI A01xx may be issued to you. The digits A01 are unique to you. You will then use the last two digits to allocate a unique code for each mould. The code for the first mould might be IFPI A0100, the code for the second IFPI A0101, and so on. Using alphanumeric digits consisting of the numbers 0 through 9 and the letters of the Western alphabet A through Z, excluding I, O, S and Q, the production licensee has the ability to assign unique codes to 1,024 different moulds.

- You should then notify your supplier of mastering equipment and moulding tools each time that you order any equipment so that they can apply the codes to the relevant equipment prior to delivery.

- You should ensure that the SID Codes are also applied to all existing moulds and LBR MIS systems. It is recommended that you contact the supplier of the equipment for advice on how to do this.

- All SID Codes must be installed in compliance with the SID Code Technical Specifications which accompany this document. These specifications set out certain criteria which must be met with regard to location on the disc, tamper resistance, wear and tear, visibility, etc.

- Finally, every plant that has been allocated a SID Code should ensure that every stamper and every disc produced in the plant should bear the appropriate SID Code or Codes.

Further details concerning the criteria and uniformity referred to can be obtained from:-

IFPI Secretariat

Telephone: + 44 (0)20 7878 7900

Facsimile: + 44 (0)20 7878 6832

E-mail: cdplant@ifpi.org

Website: http://www.ifpi.org

Philips Intellectual Property & Standards

Business Support

Telephone: + 31 40 273 4893

Facsimile: + 31 4027 32 113

Website: http://www.licensing.philips.com/information/sid/

SID CODE technical specifications

The following technical specifications apply to the use of SID Codes for CD format and high-density format optical discs.

Any company that does obtain a SID Code must comply with the following requirements:

General

The SID (Source Identification) Code is imprinted in the inner area of CD and High Density formats of Optical Discs. The SID Code consists of the letters “IFPI”, followed by either four or five additional characters, which may be alphabetical or numerical, identifying the registered number of the Laser Beam Recorder used to make the glass master or stamper, or the registered number of the mould used to press the disc. There are two kinds of SID Code, the Mastering Code and the Mould Code.

The Mastering Code must be recorded by the Laser Beam Recorder on to the surface of the glass master or stamper so that it is reproduced on every metal manufacturing part and hence every disc produced from that master or stamper. The SID Code must be installed in such a way that it is not capable of being altered or disabled by the user of the Laser Beam Recorder, i.e. it must be hardwired into firmware of the Laser Beam Recorder or embedded to the system controller.

The Mould Code must be etched on the mirror block surface of every mould. It is not acceptable to etch the mould on any removable ring.

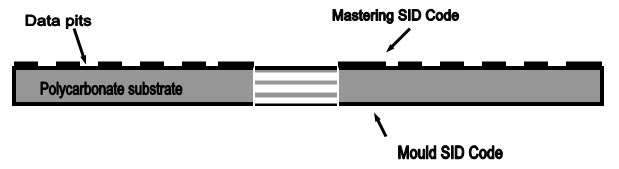

When a substrate is pressed, the Mastering Code must be recorded on the same side of the substrate on which the embossed data pits are recorded, and the Mould Code must be recorded on the other side of the substrate.

Mould SID Code: Technical Specifications

Each Mould SID Code that is assigned will consist of the letters "IFPI" followed by a four or five digit code. The last two digits of this code are allocated by the person to whom the SID Code has been assigned to give each mould on the site, including spare moulds, a unique code. The first two digits (in the case of a four digit SID Code) or the first three digits (in the case of a five digit SID Code) are assigned to the operator of the manufacturing or mastering plant by Philips Intellectual Property & Standards.

Example:

A Mould SID Code of "IFPI A01" may be issued to the operator of a manufacturing plant. The digits "A01" are unique to the facility operator. The facility operator must then use the last two digits to allocate a unique code for each mould. The code for the first mould might be IFPI A0100, the code for the second "IFPI A0101", and so on. Using alphanumeric digits consisting of the numbers 0 through 9 and the letters of the Western alphabet A through Z, excluding "I", "O", "S" and "Q", the production licensee has the ability to assign unique codes to 1,024 different moulds.

The Mould SID Code must:

1. Be etched on the mirror block of each mould, or a component of the mould that is not easily detachable from the mirror block, so that the Mould SID Code is moulded on the read-out, or play surface of each disc during the manufacturing process. The Mould SID Code may not be etched on any easily removable ring, or applied to the other (stamper) side of the disc.

2. Be positioned at a radius of between 7.5 mm and 22 mm from the centre of the disc, except in the case of high density format discs (see section following).

3. Have a character height of between 0.5mm and 1.0mm.

4. Be etched to a depth of between 10 to 25 microns and be legible, without magnification, throughout the life of the mould.

5. Read from left to right when viewed from the read-out, or play side of the disc.

6. The digits "IFPI" must be in upper case characters and may have either a linear or a radial layout.

Additional Requirements and Variations for High Density Disc Formats Such As DVD and SACD.

The allocated Mould SID Codes should be used in the production of both CD format discs, and high density disc formats. However, there are some variations in the standard for applying these codes, as set out below.

1. The Mould SID Code must be positioned within the zone that has a maximum radius of 22.5 mm.

2. If BCA-Code is used, then the position of the Mould SID Code will be adjusted to compensate.

3. The Mould SID Code must not be imprinted in the clamping area.

4. The Mould SID Code must not be placed in an area that obscures the Mastering SID Code or any other user defined characters.

5. The Mould SID Code must be imprinted on all substrates whether containing valid programme content or not, including blank discs, and even if not metallised. Overprinting of the Mould Code for decorative purposes is permissible.

Mastering SID Code: Technical Specifications

Each Mastering SID Code that is assigned will consist of the digits "IFPI" followed by a four or five digit code commencing with the letter "L". A manufacturer will be assigned a batch of sequential codes and must assign a unique code to each separate LBR on the site.

The Mastering SID Code must be added to the matrix band of the master during exposure on the Laser Beam Recorder. All subsequent metal manufacturing parts (incl. mothers and stampers) and all discs manufactured from that master will then bear the code. The LBR supplier will be able to install this once advised of the specific code allocated to each LBR.

The Mastering Code must:

1. Be positioned between 18.0 mm from the centre of the disc and the start of the "lead-in" (which is at a radius of 22.9 mm from the centre).

2. Be a minimum of 0.5 mm high.

3. Be legible without magnification.

4. Be located in the metallised region of the disc.

5. Read from left to right when viewed from the read-out , or play side of the disc.

6. Be installed in either the firmware of the Laser Beam Recorder (i.e. the software that forms an intrinsic part of the machinery and is not readily accessible by the operator of the facility) or embedded in the system controller (i.e. the signal processing system that controls the operation of the LBR) in such a way that the operator of the system is not able to alter the code.

7. It is recommended that the space allocated exclusively for the code (determined by the user and LBR supplier) shall consist of an arc of 30 for the Mastering SID Code. It is mandatory that it is clearly separate from other features.

Additional Requirements for High Density Disc Formats Such As DVD and SACD.

The allocated Mastering SID Codes should be used in the production of both CD format discs, and high density disc formats. However, there are some variations in the standard for applying these codes, as set out below.

1. The Mastering SID Code must be placed within the zone that has a maximum radius of 22.5 mm.

2. If BCA Code is used, then the position of the Mastering Code should be adjusted to compensate.

3. No minimum radius is specified, but due regard should be paid to the following points:

- The Mastering SID Code must be located in a metallised region of the disc.

- The Mastering SID Code must not be obscured by the stack ring.

- It is recommended that the space allocated exclusively for the code (determined by the user and LBR supplier) shall consist of an arc of 30 for the current code. It is mandatory that it is clearly separate from other features.

- A further arc of 30 shall be reserved for future use.

Disc Variations

- For the single layer, single side disc.

-

If the dummy side of the disc is made from a scrap program disc, it shall bear the SID Code, even if not metallised.

- For the dual layer, single side disc

The Mastering SID Code must be recorded for both layers (Layer 1 and Layer 0 in DVD format discs). At least one of the Mastering SID Codes (for either Layer 1 or Layer 0) must be clearly visible.

- For the single layer, double side disc.

The Mastering SID Codes must be recorded on both sides of the disc. It is desirable that both Mastering SID Codes are clearly visible, but it is acceptable if the code is obscured due to restrictions of the printed area.

- For Hybrid SACD discs (one high-density layer and one CD layer)

The Mastering SID Code must be recorded on both layers. It is desirable that both Mastering SID Codes are clearly visible, but it is acceptable if the code is obscured due to restrictions of the printed area.

IFPI, International Federation of the Phonographic Industry

For further information please contact:

Samantha Wright

SID Code Administrator

IFPI Secretariat

54 Regent Street

London W1B 5RE

Telephone: + 44 (0)20 7878 7900

Facsimile: + 44 (0)20 7878 6832

E-mail: cdplant@ifpi.org

Website: http://www.ifpi.org

Philips Electronics BV

Application for SID CODE numbers to:

Philips Intellectual Property & Standards

Business Support

Building SFF-8,

PO Box 80002

5600 JB Eindhoven

The Netherlands

Telephone: + 31 40 273 4893

Facsimile: + 31 40 273 2113

Website: http://www.licensing.philips.com/information/sid/

|

|

|

|